GIA CÔNG CƠ KHÍ

Gia công cơ khí là một trong những thế mạnh của Cơ khí Tùng Yên. Chúng tôi rất hân hạnh đồng hành cùng Quý khách với những dịch vụ gia công:

TƯ VẤN, THIẾT KẾ, CHẾ TẠO CƠ KHÍ

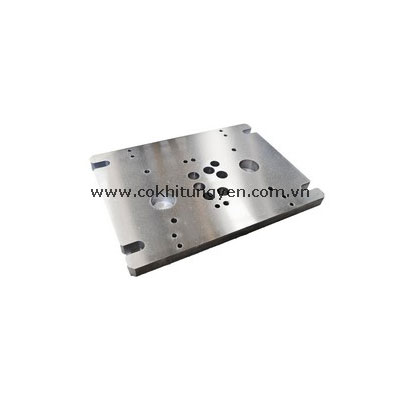

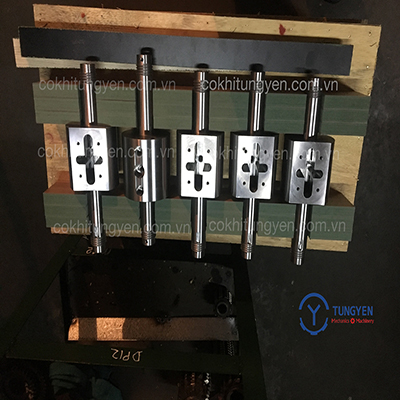

Cơ khí Tùng Yên sở hữu đội ngũ chuyên gia lâu năm trong lĩnh vực cơ khí cùng kinh nghiệm thực tiễn với hàng nghìn đơn hàng luôn đem đến dịch vụ chất lượng cao nhất trong tư vấn, thiết kế chế tạo cơ khí cho khách hàng:

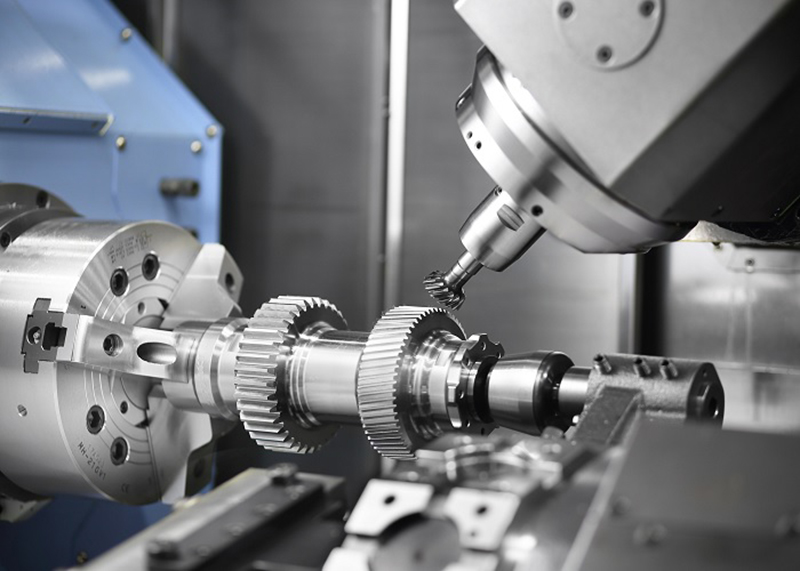

CHUYÊN CÁC LOẠI BÁNH RĂNG, TRỤC VÍT…

Cơ khí Tùng Yên với truyền thống và kinh nghiệm lâu năm trong gia công cơ khí luôn cam kết đảm bảo về chất lượng sản phẩm, hình dáng kích thước chính xác tuyệt đối trong các chi tiết sản phẩm:

Thiết kế – Chế tạo – Gia công

LÝ DO KHIẾN KHÁCH HÀNG LỰA CHỌN CƠ KHÍ TÙNG YÊN

Cơ khí Tùng Yên là lựa chọn số 1 trong gia công cơ khí đạt được sự tin yêu đặc biệt của khách hàng với nhiều lợi ích thiết thực như:

– Đảm bảo sản phẩm với chất lượng tốt nhất

– Giá cả tốt nhất thị trường

– Nhận gia công sản phẩm cơ khí theo yêu cầu khách hàng

– Nguyên liệu đầu vào chất lượng, ổn định

Thiết kế – Chế tạo – Gia công

sản phẩm tiêu biểu

Công ty cơ khí Tùng Yên chuyên tư vấn, thiết kế và gia công chế tạo cơ khí với đa dạng sản phẩm, chi tiết máy theo yêu cầu của Quý khách hàng trên toàn quốc

TIN TỨC NỔI BẬT

Thường xuyên cập nhật bài viết của chúng tôi để hiểu thêm nhiều kiến thức mới mẻ trong lĩnh vực cơ khí…

Liên Hệ Ngay

Để Được Tư Vấn Miễn Phí

“Tùng Yên là thương hiệu uy tín hàng đầu về chất lượng gia công cơ khí tại Việt Nam. Với thế mạnh về gia công bánh răng và chi tiết máy công nghiệp, chúng tôi luôn áp dụng những công nghệ mới nhất vào quy trình làm việc để rút gọn thời gian, đảm bảo tiến độ, tiết kiệm được sức lao động, mang đến sản phẩm đạt được chất lượng cao nhất”

![[Số 1 VN] Gia công bánh răng vi sai chất lượng cao theo yêu cầu 16 Gia công bánh răng vi sai](https://tyc.com.vn/wp-content/uploads/2018/09/banh-rang-vi-sai.jpg)